Product Description

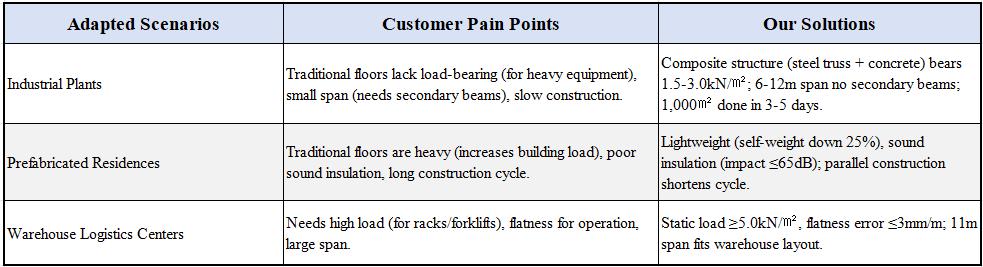

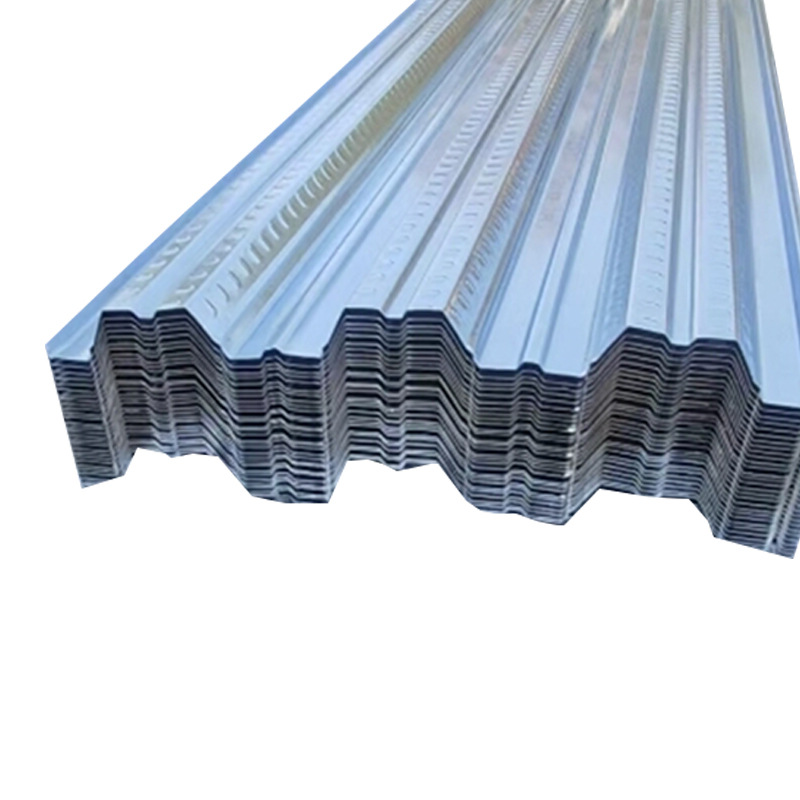

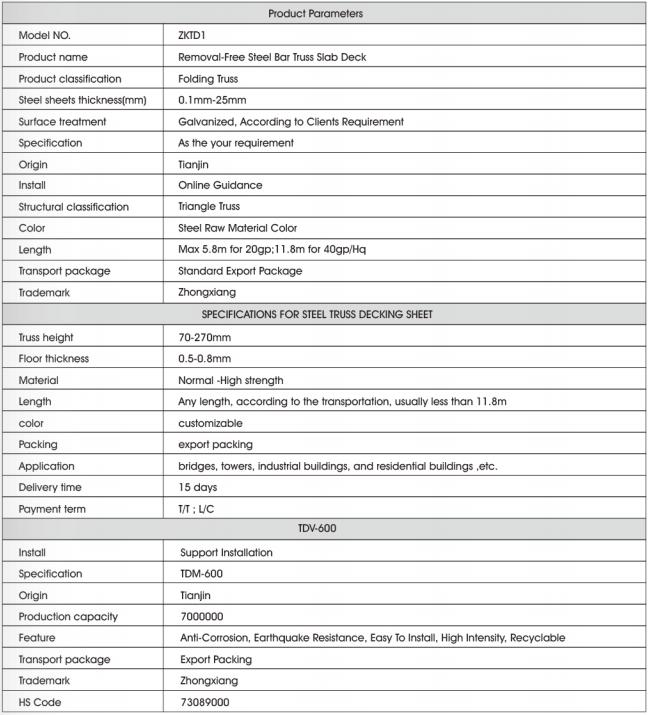

Steel Truss Floor Bearing Plates | Steel-Truss + Concrete Combination・High Load-Bearing・Fast Construction・Space-SavingFull-process service from structural design to on-site installation guidance, suitable for industrial plants, multi-storey office buildings, warehouse logistics centers, and prefabricated residential buildings

Why Choose Our Steel Truss Floor Bearing Plates?

1. Product Performance: Stable Load-Bearing, Strong Durability

High Composite Bearing Capacity: Adopts steel-truss + concrete composite structure, with excellent bending resistance; can bear 1.5-3.0kN/㎡ live load (suitable for equipment placement, personnel movement), and static load capacity ≥5.0kN/㎡.

Large Span & High Space Utilization: No secondary beams required for spans of 6-12m, reducing floor height occupation by 20%-30% compared to traditional reinforced concrete floors; flexible for building interior layout.

Strong Crack Resistance: Steel truss disperses stress evenly, effectively preventing concrete cracking; after pouring, the floor has good 整体性 (integrity) and can resist Level 7 earthquakes.

2. Construction & Cost: Efficient, Economical, Labor-Saving

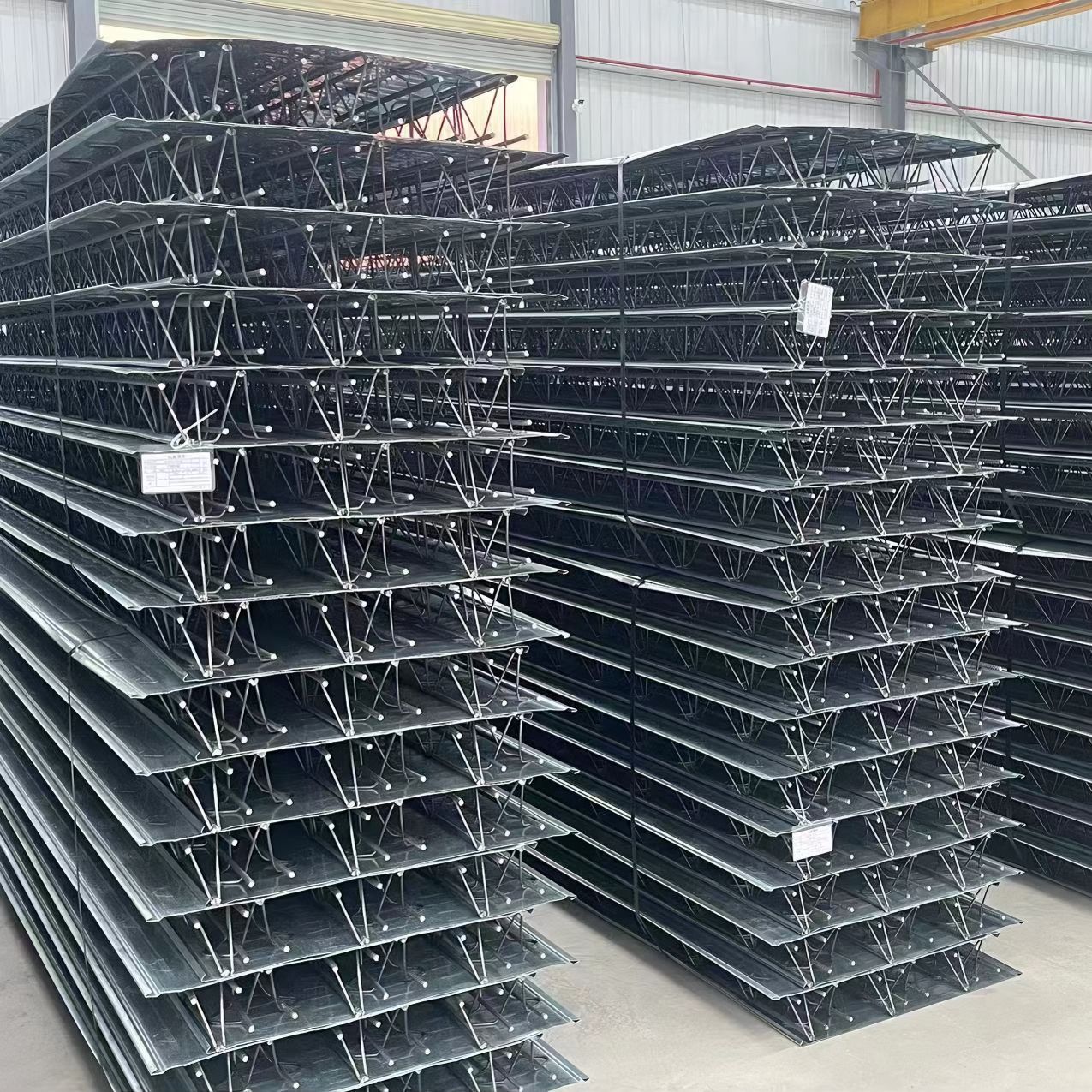

Ultra-Fast Construction: 80% of components are factory prefabricated (steel truss + bottom steel plate); on-site only needs laying, binding steel bars, and pouring concrete. 1,000㎡ floor can be completed in 3-5 days, 50% faster than traditional formwork.

Low Comprehensive Cost: Eliminates the need for traditional wooden/steel formwork disassembly, saving 30%-40% of formwork and labor costs; reduces on-site wet work (concrete pouring volume decreased by 15%), lowering material waste.

Easy Coordination: Can be constructed in parallel with the main steel structure (no need to wait for the main structure to be fully completed), shortening the overall project cycle by 10-15 days.

3. Full-Process Service: Worry-Free, One-Stop Support

Early Stage: Customized structural design (based on building height, span, and load requirements) + detailed construction drawings (including truss layout, pouring thickness).

Later Stage: On-site installation guidance (professional team to check laying accuracy) + post-construction acceptance support (load testing, crack inspection).

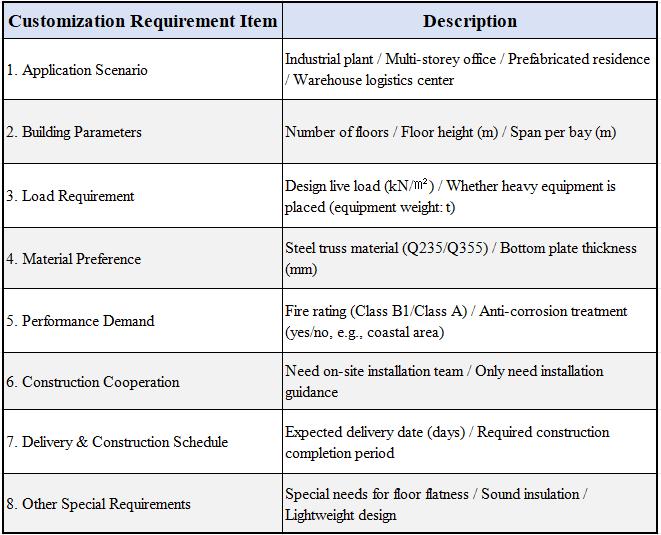

How to Customize Your Steel Truss Floor Bearing Plates?

FAQ

- Are your steel truss floor bearing plates factory-produced or on-site processed?

A: We are a factory with professional truss welding and bottom plate compounding lines; all products are prefabricated in the factory, ensuring consistent quality and reducing on-site processing time.

Q.What advantages do your products have over traditional reinforced concrete floors?

A: Our products are 50% faster to construct, 25% lighter in self-weight (reducing building load), and save 30%-40% of formwork costs; they also allow parallel construction with the main structure, shortening the overall project cycle.

Q.Do you provide load testing reports for the floor after installation?

A: Yes, we can arrange third-party testing institutions to conduct static/dynamic load tests and provide formal test reports to ensure the floor meets design requirements.

Q.What is the delivery time for customized steel truss floor bearing plates?

A: Regular specifications (truss height 150-200mm, width 900mm) are delivered within 7-10 days; special specifications (e.g., truss height >250mm, high-load design) take 12-15 days.

Company Information

ZhongXiang Steel Structure (Tianjin) Co., Ltd • Professional manufacturer of steel structure supporting products with full-process service

Product Inquiry

Interested in this product? Send us your requirements and we'll get back to you with a quote.

Thank You!

Your inquiry has been sent successfully. We'll get back to you soon.