Product Description

Flat Pack Container Houses are “modular prefabricated living & working spaces” designed based on users’ demands for mobility, space efficiency and cost-effectiveness.

What are Flat Pack Container Houses?

Typically, a Flat Pack Container House is made of three distinctive parts:

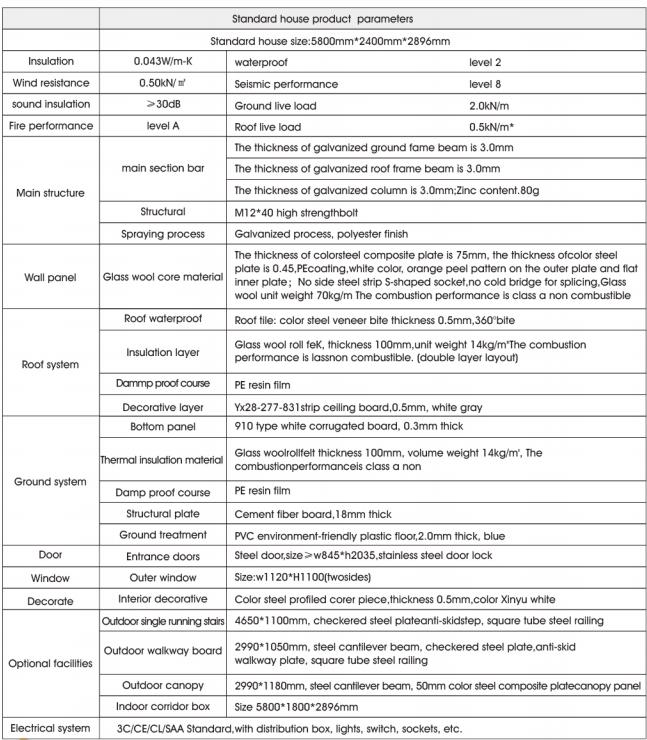

– Main structural modules (container frame, wall panels, roof panels)**, which are prefabricated steel structures with standardized dimensions, featuring high strength and durability to ensure structural stability.

-Secondary assembly components (connecting hardware, insulation layers, decorative finishes)**, which are lightweight accessories that enable quick assembly and provide thermal insulation and aesthetic enhancement.

-Integrated facility systems (electrical wiring, plumbing, lighting fixtures)**, which are pre-configured internal systems to meet basic living or working needs.

All the main structural modules and secondary assembly components are pre-produced, pre-cut, pre-drilled and pre-finished in the factory before being transported to the site for assembly.

The pre-fabricated components are then fixed and joined via bolted connections or interlocking mechanisms at the job site.

Who is Suitable for Flat Pack Container Houses?

– Construction workers and project teams needing temporary on-site accommodation and office spaces for infrastructure projects.

– Investors and operators aiming to develop affordable housing communities, pop-up commercial spaces or innovative co-living projects.

– Humanitarian organizations and government agencies requiring quick-deployable shelters for disaster relief or temporary resettlement.

Popular Regions for Flat Pack Container Houses

They are widely used in rapidly developing regions of Southeast Asia (such as Vietnam, Indonesia) for urbanization projects and industrial site accommodations. They are also gaining popularity in European countries (like Germany, France) for eco-friendly modular housing experiments. In China, especially in megacities like Shanghai and Shenzhen, they are commonly adopted for construction site dormitories and temporary commercial venues.

What are Guard Houses?

Typically, a Guard House consists of three core components:

·Main structural modules (living module, rest module, basic functional module): These are prefabricated integrated units made of high-strength and durable materials (such as color steel plates, light steel structures). The space layout is optimized according to the number of on-site workers and living habits, and basic living functions such as rest, dining and washing are integrated.

·Auxiliary supporting components (insulation layers, waterproof components, safety protection parts): They are professional components matched with the main structure. The insulation layer adapts to high and low temperature environments, the waterproof components ensure the dryness of the room in rainy and snowy weather, and the safety protection parts (such as anti-collision bars, fire-fighting facilities) improve the safety of the space.

·Basic facility systems (power supply system, lighting system, ventilation system): They are practical systems configured for on-site use. The power supply system can be connected to on-site temporary power or equipped with a generator set for independent power supply; the lighting system meets the needs of day and night use; the ventilation system ensures air circulation in the room and improves living comfort.

All main structural modules and auxiliary supporting components are pre-produced, pre-installed, pre-tested and pre-decorated in the factory. They are then transported to the construction site and quickly assembled through standardized connecting parts, which greatly shortens the on-site construction cycle.

Who is Suitable for Guard Houses?

·On-site workers in construction, road construction, bridge construction and other engineering projects who need long-term or short-term on-site accommodation.

·Staff in mining areas, oil fields, remote construction sites and other areas with relatively harsh environments who need stable and safe living spaces.

·Project managers, supervisors and other management personnel who need on-site office and rest spaces to facilitate on-site command and coordination.

Popular Regions for Guard Houses

Guard Houses are widely used in various engineering construction sites across China, especially in large-scale infrastructure construction projects in the western region and urban renewal projects in eastern cities. They are also widely used in mining areas and oil fields in Australia and Canada, where remote working environments have a strong demand for durable and practical on-site living spaces. In addition, in southeast Asian countries (such as Vietnam and Thailand) with booming infrastructure construction, the demand for Guard Houses is also increasing year by year, adapting to the needs of local engineering construction.

Why Choose Guard Houses?

·Durable & Adaptable to Harsh Environments: Made of high-strength and wear-resistant materials, equipped with professional insulation and waterproof structures, Guard Houses can adapt to various harsh environments such as high temperature, low temperature, rainy season and dry season, ensuring stable use in different regions and climates. Compared with traditional temporary houses, they have better durability and service life.

·Quick Assembly & Flexible Relocation: The prefabricated module design allows on-site assembly to be completed in a short time (usually 1-3 days for a single house). At the same time, the overall structure is light and easy to disassemble. When the project is completed or the construction site is transferred, it can be quickly disassembled and relocated to other sites for reuse, reducing resource waste.

·Integrated Function & Comfortable Experience: Integrating living, rest, washing and other multiple functions, the internal space is reasonably divided. It can be equipped with bunk beds, lockers, simple stoves and other facilities according to needs, providing workers with a relatively comfortable living environment and improving on-site living quality.

·Cost-Effective & Safe and Reliable: The prefabricated production mode reduces on-site construction costs and labor costs. The standardized production process ensures product quality. At the same time, it is equipped with complete fire-fighting facilities, anti-collision structures and other safety configurations to effectively ensure the personal safety of on-site workers.

Product Inquiry

Interested in this product? Send us your requirements and we'll get back to you with a quote.

Thank You!

Your inquiry has been sent successfully. We'll get back to you soon.