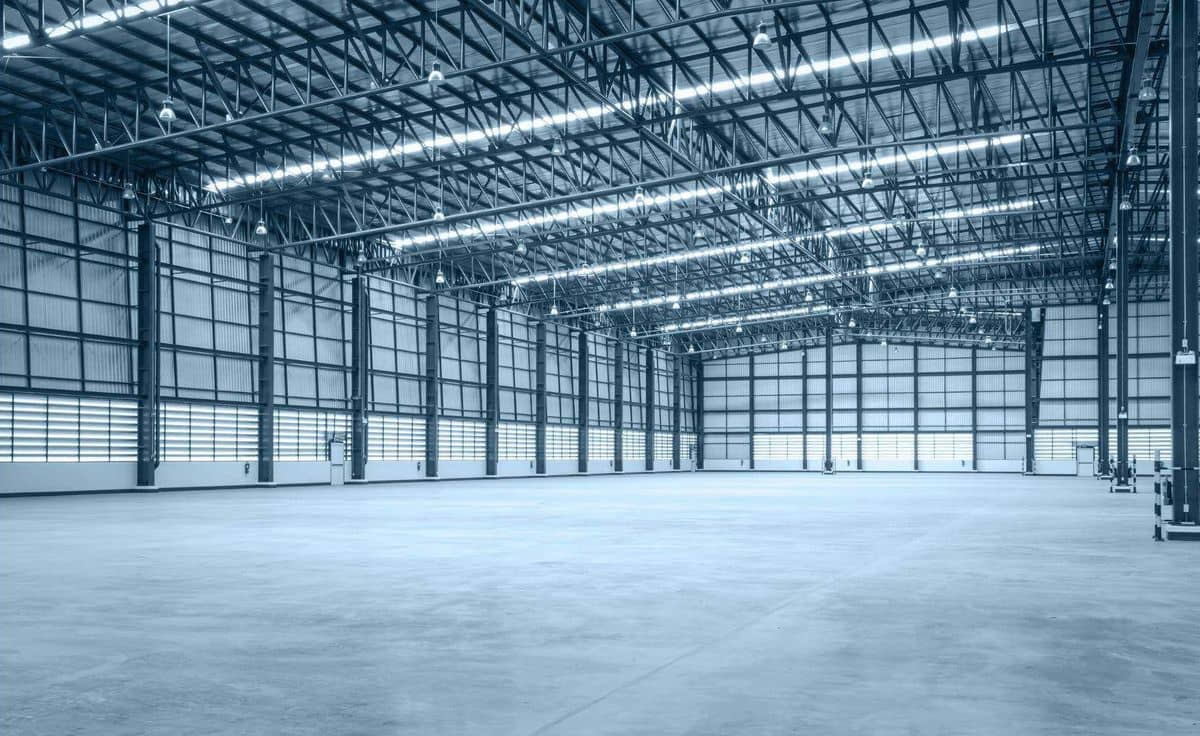

Product Description

Steel structure warehouse workshops use high-strength steel as the main load-bearing structure (such as H-beams, I-beams, channel steels, etc.), combined with enclosure systems (color steel plates, sandwich panels, etc.) and supporting facilities (ventilation, fire protection, lifting equipment, etc.), forming an industrial space with both storage and production functions. Their core characteristics can be summarized into the following five points:

WHY CHOOSE US

1. Structural Performance: Combining High Strength and Stability

Strong Load-Bearing Capacity:

The tensile and compressive strength of steel is several times that of concrete. It can support large-span,and large-space designs, without the need for too many column partitions, which can maximize the use of internal area.

Excellent Wind and Earthquake Resistance:

The self-weight of the steel structure is light, and the material has good toughness. It can absorb energy through its own deformation during natural disasters such as earthquakes and strong winds. The structural safety is far superior to that of traditional buildings.

Outstanding Durability:

Through hot-dip galvanizing, anti-corrosion coating and other process treatments, steel can effectively resist humid and corrosive environments. Moreover, the later maintenance cost is low.

2. Flexible Design: Adapting to Diverse Needs

Space Customization:

The span and height can be flexibly adjusted according to the production or storage needs of enterprises . It even supports later expansion.

Functional Integration:

It can simultaneously integrate ventilation systems, lighting belts (FRP lighting panels, saving daytime lighting energy consumption), fire protection systems, and lifting equipment, realizing the integration of “storage + production + logistics”.

Simple and Modern Appearance:

The enclosure system can use color steel plates, aluminum-magnesium-manganese plates and other materials, combined with different colors and textures. It can not only meet the practicality of industrial buildings, but also improve the overall aesthetics of the factory area, adapting to the image of modern enterprises.

3. Construction and Cost: Significant Advantages in Efficiency and Economy

Short Construction Period: Most steel structure components are prefabricated in factories, and only on-site assembly is required (the assembly rate can reach more than 80%). Compared with concrete buildings, the construction period can be shortened by 40%-60%. For example, a 10,000-square-meter warehouse workshop can be completed in only 2-3 months, helping enterprises to put into production quickly.

High Cost Controllability: On the one hand, prefabricated production reduces on-site labor and material waste, lowering the construction cost; on the other hand, steel can be recycled (the recycling rate is more than 90%). If the building is demolished later, it can reduce resource waste and secondary costs, and the long-term economy is prominent.

4. Environmental Protection and Sustainability: Conforming to the Trend of Green Development

Low-Carbon Emission Reduction:

The energy consumption in the steel structure production process is lower than that of concrete. Moreover, there is no wet work in on-site construction, which reduces dust, noise and construction waste emissions, conforming to the national “dual carbon” policy requirements.

Recyclable Utilization:

After the building is demolished, steel can be reprocessed for other projects, avoiding the landfill pollution of traditional construction waste. At the same time, the enclosure materials can also be partially recycled, realizing the recycling of resources and enhancing the green image of enterprises.

Product Inquiry

Interested in this product? Send us your requirements and we'll get back to you with a quote.

Thank You!

Your inquiry has been sent successfully. We'll get back to you soon.