Product Description

Greenhouses are “steel-structured plant & livestock cultivation spaces” designed based on the agricultural, horticultural and animal husbandry requirements of users.

What are Greenhouses?

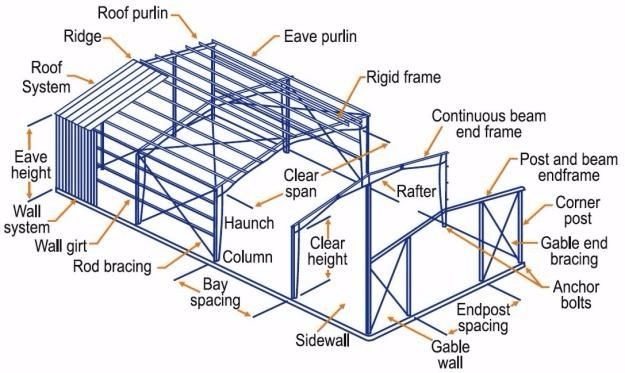

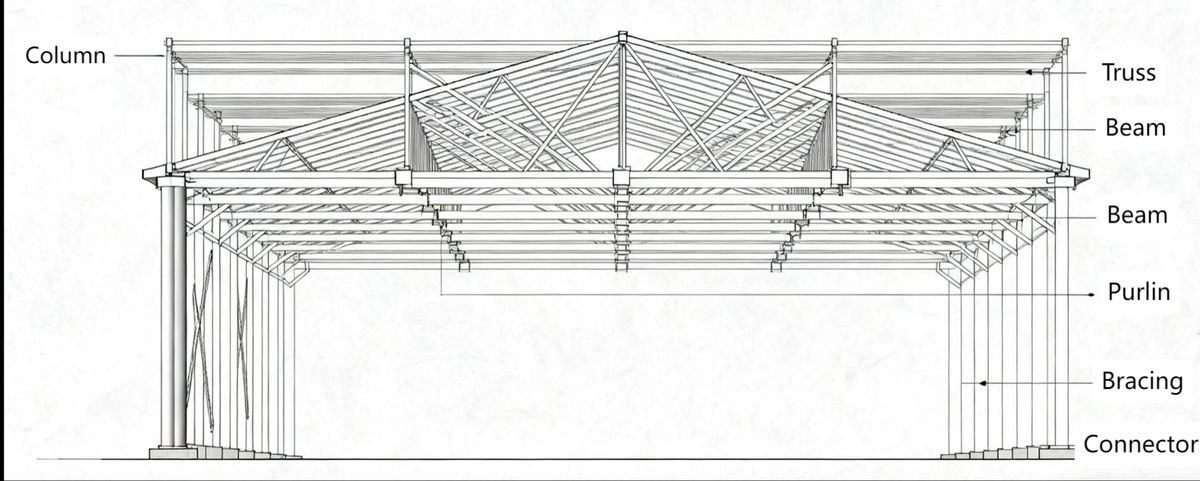

Typically, a Greenhouse is made of three distinctive parts:

- Primary steel framing members (columns, trusses, beams), which are hot-dip galvanized steel sections with reinforced structural design, ensuring sufficient load-bearing capacity to support covering materials, equipment and resist wind, snow and live loads.

- Secondary structural components (purlins, bracing, connectors), which are light-weight cold-formed steel members that enhance overall stability and facilitate the installation of covering materials and auxiliary facilities.

- Covering materials (polycarbonate sheets, glass, film), which are translucent or transparent materials (or opaque for animal husbandry) providing light transmission (or shading), thermal insulation and weather resistance for plant growth or livestock breeding.

All the primary steel framing members and secondary structural components are pre-cut, pre-drilled, pre-welded, and pre-galvanized in the factory before being transported to the site for erection.

The pre-fabricated components are then fixed and joined via bolt and nut connections or specialized fasteners at the job site.

Advantages of Greenhouses

- Structural Durability & Stability

The hot-dip galvanized steel structure offers excellent corrosion resistance, ensuring a service life of 15-20 years even in humid or corrosive environments. The optimized structural design enables it to withstand strong winds (up to 12 levels) and heavy snow loads (up to 0.5kN/m²).

- Customization & Scalability

It can be customized in size, shape and internal layout according to different cultivation needs (e.g., height adjustment for tall plants, multi-span design for large-scale production). The modular steel structure allows for easy expansion or modification when production scale changes.

- Environmental Control Efficiency

The steel structure supports the installation of advanced environmental control systems (such as temperature regulators, humidity controllers, and automatic ventilation devices), enabling precise control of the internal environment to meet the optimal growth conditions for plants or livestock.

- Cost-Effectiveness & Quick Installation

The prefabricated steel components reduce on-site construction time and labor costs, with a typical installation cycle of 1-2 weeks for a standard greenhouse. The long service life and low maintenance costs make it a cost-effective choice in the long run.

Product Inquiry

Interested in this product? Send us your requirements and we'll get back to you with a quote.

Thank You!

Your inquiry has been sent successfully. We'll get back to you soon.